Controlled Flexing Expansion Joints

Senior Flexonics Canada Controlled Flexing Expansion Joints combine a corrugated pressure carrier with closely mated neck rings and reinforcing or control rings. This

construction permits their use with higher pressures (150 psig and 300 psig) in applications where large amounts of axial movement are required.

Dual expansion joints are available for applications where movement is greater than can be absorbed by a single unit. Contact factory for design information.

PDF Reference Guide Controlled Flexing Expansion Joints

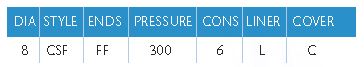

How to Order:

Example P/N

Controlled Flexing Data

- Size Range – 3″ to 18″ *NPS

- Allowable Pressure Stainless Steel Bellows – Vacuum to 300 psig

- Temperature Limits Stainless Steel Bellows – -20°F to 800°F. **

- Axial Traverse – To 7 1/2″…(depending on size)

- Lateral Motion- Up to 1 1/2″…(depending on size)

* For sizes larger than 18” consult factory for information. **With special alloys, temperatures of minus 425°F. to plus 1600°F. can be handled.

Materials of Construction

- Bellows: ASTM A240 T3o4 (standard)

Other materials available - Pipe: ASTM A53/A106

50 lb. Series: Sch. 40

150 lb. Series: Sch. 40

300 lb. Series: Sch. 40 - Flanges: A516-70 Plate (Std) ATSM A105 (Opt)

50 lb. Series: 150 lb. ANSI B16.5 R.F.S.O.

150 lb. Series: 150 lb. ANSI B16.5 R.F.S.O.

300 lb. Series: 300 lb. ANSI B16.5 R.F.S.O. - Covers: Carbon Steel

- Tie Rods: Carbon Steel

- Liners: 300 Series Stainless Steel

- Rated cycle life is 2000 cycles per EJMA 8th edition for any one movement tabulated.

- To combine axial, lateral movements, refer to page 7.

- Maximum axial extension movement is 10% of tabulated axial value.

- To obtain greater movements or cycle life, contact the factory.

- Catalogue pressure ratings are based upon a maximum bellows temperature of 800°F. Actual operating temperature should always be specified.

- Maximum test pressure: 1 1/2 x maximum working pressure.