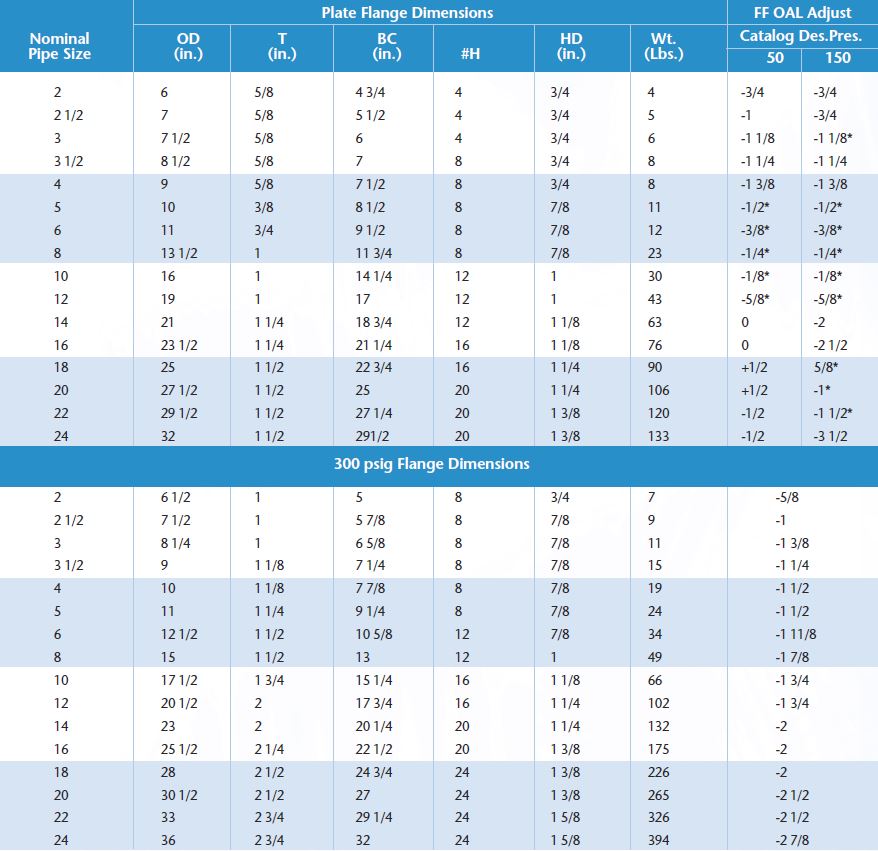

Standard Flange Data

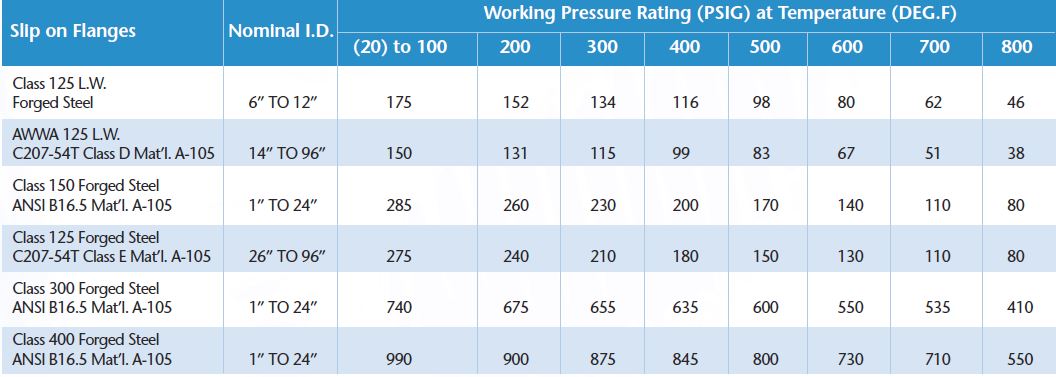

This abbreviated flange data summary is to aide system designers in selecting the optimum pipe and duct flanges. The working pressure at temperature ratings were obtained from applicable flange specifications. Where elevated temperature data was not available, the rated working pressure at ambient was down rated in accordance with ASME code versus temperature correction factors.

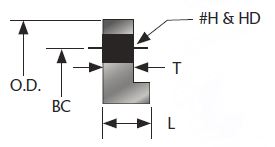

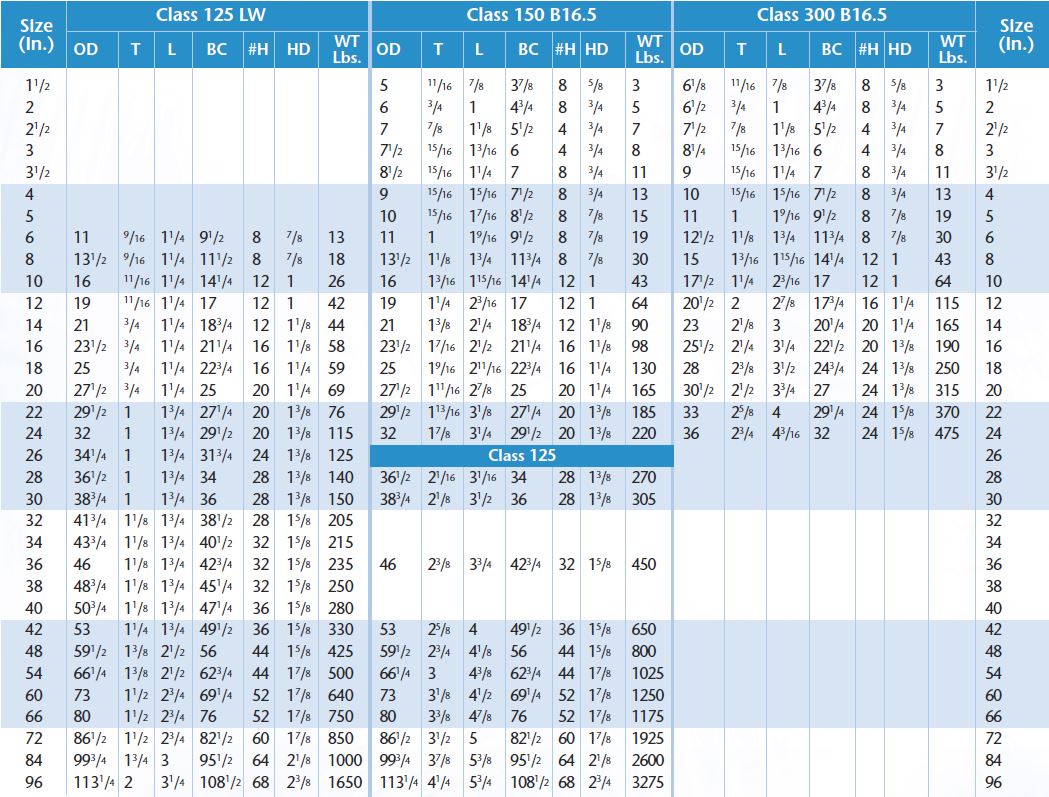

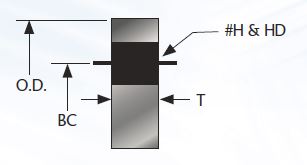

The dimensional data shown below has been consolidated from current standards for easy reference. All dimensions are in inches.

The dimensional data shown below has been consolidated from current standards for easy reference. All dimensions are in inches.

To Select the overall length of an assembly that uses plate flanges, use the FF (Flange by Flange overall length from the data page and adjust the overall catalogue overall length by the amount shown in the column labelled FF OAL adjust.

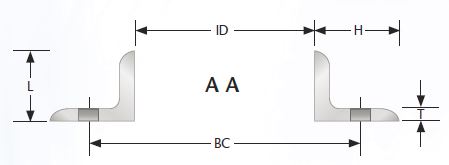

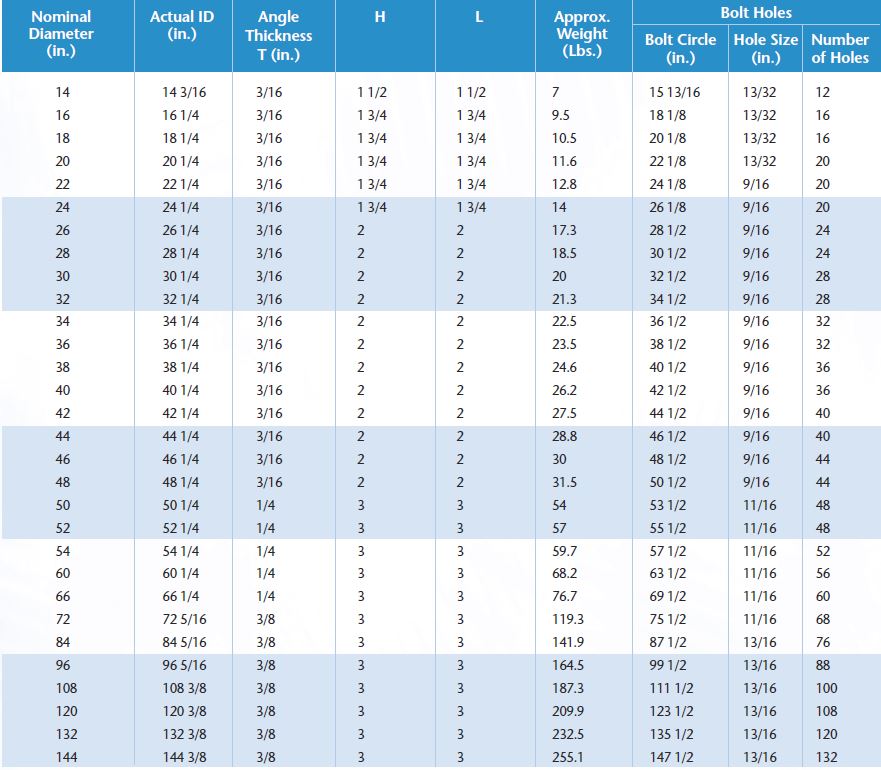

Angle Flanges – Low Pressure

5 PSIG Max

- Economical flanges for low pressure service <5.

- Cap can be added to single and universal expansion joints. See part number below.

- Material: carbon steel. (other materials are available on request).

- Single overall length using angle flanges=WW OAL – 6 inches + 2*L.

Notes:

- Plate Flanges are designed for use with sheet gasket.

- Flange gasket seating surface is a smooth mill finish.

- Not recommended for use with spiral wound gaskets.

- A36 material not recommended for use above 700F. or below 20F.

- Not suggested for applications where ASME B31.3 or SectionVIII Pressure Vessel Code requirements apply.

- Standard Catalogue Flanges: 50 psig design/Class 125 L.W., 150 psig design/Class 150, 300 psig design/ Class 300

- * Length difference includes space required to avoid interference with bellows and flange nuts.