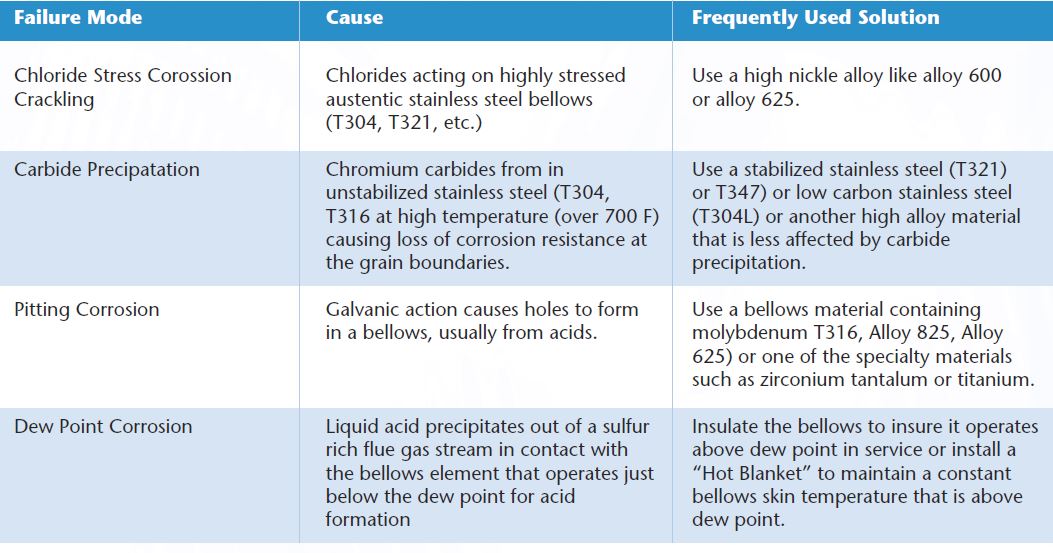

Materials – Common Metallurgical Problems

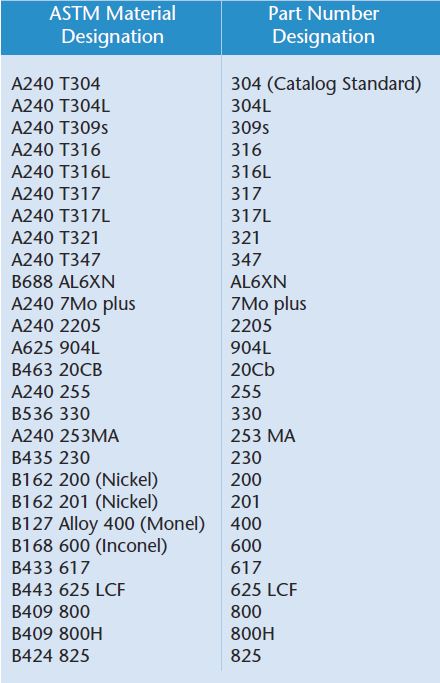

Standard Material Specifications for Bellows

Bellows Material Data

Senior Flexonics engineers can form bellows from most ductile materials that can be welded by the automatic TIG butt welding process that results in a homogenious ductile weld structure. Companies specifying and purchasing bellows must give careful consideration to the selection of bellows material. When in doubt, consult with basic supplier mill Metallurgist. Senior Flexonics does not take responsibility for alloy selection.

Use of these materials codes as a suffix in the Catalogue part number will designate the bellows material that will be supplied by Senior Flexonics.

* ASME “SA” or “SB” materials are inventoried and are available upon request.

All bellows material purchased by Senior Flexonics is “mill annealed” in accordance with ASTM or ASME specification. Senior Flexonics does not perform any other heat treating operations before welding, after welding before forming convolutions or after forming convolutions unless specified by purchaser. Heat treatment of bellows after forming convolutions can lower bellows spring rate “squirm” pressure, and cycle life. Senior Flexonics does not recommend heat treatment be performed unless the bellows is operating at high temperature where time dependent properties of creep and stress rupture become significant.