Welded Metal Bellow Benefits:

Edge welded bellows are ideally suited for high cycle life applications requiring stroke in a constrained envelope.

Stroke Comparison of Edge Welded Bellows:

Stroke of edge welded bellow

- Stroke up to 90% in compression

- Stroke up to 30% in extension

Stroke of a typical formed bellow

- Stroke limited to 10%

Flexibility characteristics of an Edge Welded Bellow:

Flexibility

- Edge welded bellows are capable of softer spring rate

- Axial, angular and radial

How Edge Welded Metal Bellows are manufactured:

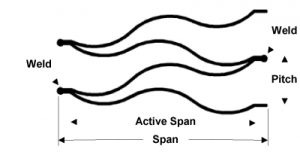

Welded diaphragm metal bellows are composed of two contoured diaphragms – each constructed from thin stainless steel – are welded at the inside diameter to form a convolution. Capsules are formed when convolutions are stacked on a horizontal arbor and welded at the outside diameter.

Edge Welded Metal Bellows Terminology:

Types of Edge Welded Metal Bellows:

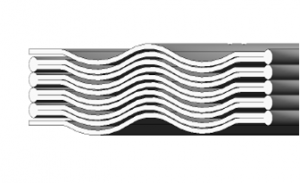

Resting Ripple Bellows:

Most welded diaphragm metal bellows have a nested ripple diaphragm configuration that provides maximum stroke, minimum stress, superior flexibility, and full nesting when collapsed or compressed.

- Long Stroke Capability

- Compact Nested Length

- Good Linearity

- Moderate Pressure Capability

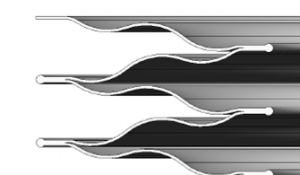

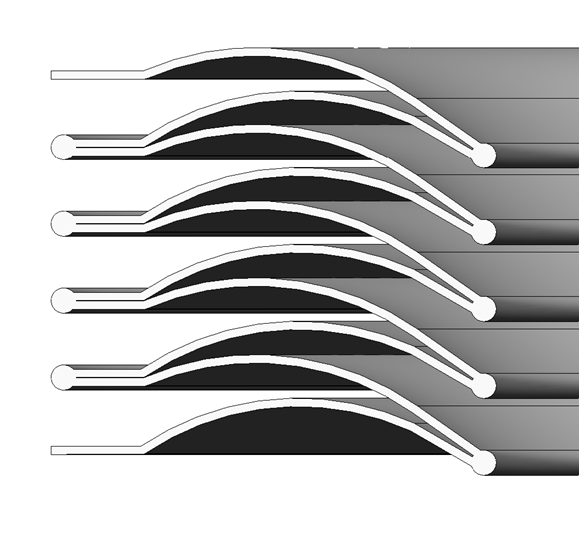

Single Sweep Bellows:

Customized bellows, including those with flat plate, single sweep, and torus contours are available for special applications.

- Good Pressure Capability

- Good Stroke Capability

- Compact Nested Length

- Good Linearity